Cylindrical parts measured to the tightest tolerances

No more crooked, improperly aligned parts – with precision-measured cylindrical parts, you can trust that your output is always on point.

The VICIVISION TECHNO is the industry-renowned leader in precision turned part measurements offering the technological expertise to ensure your parts are aligned to the tightest tolerances each and every time.

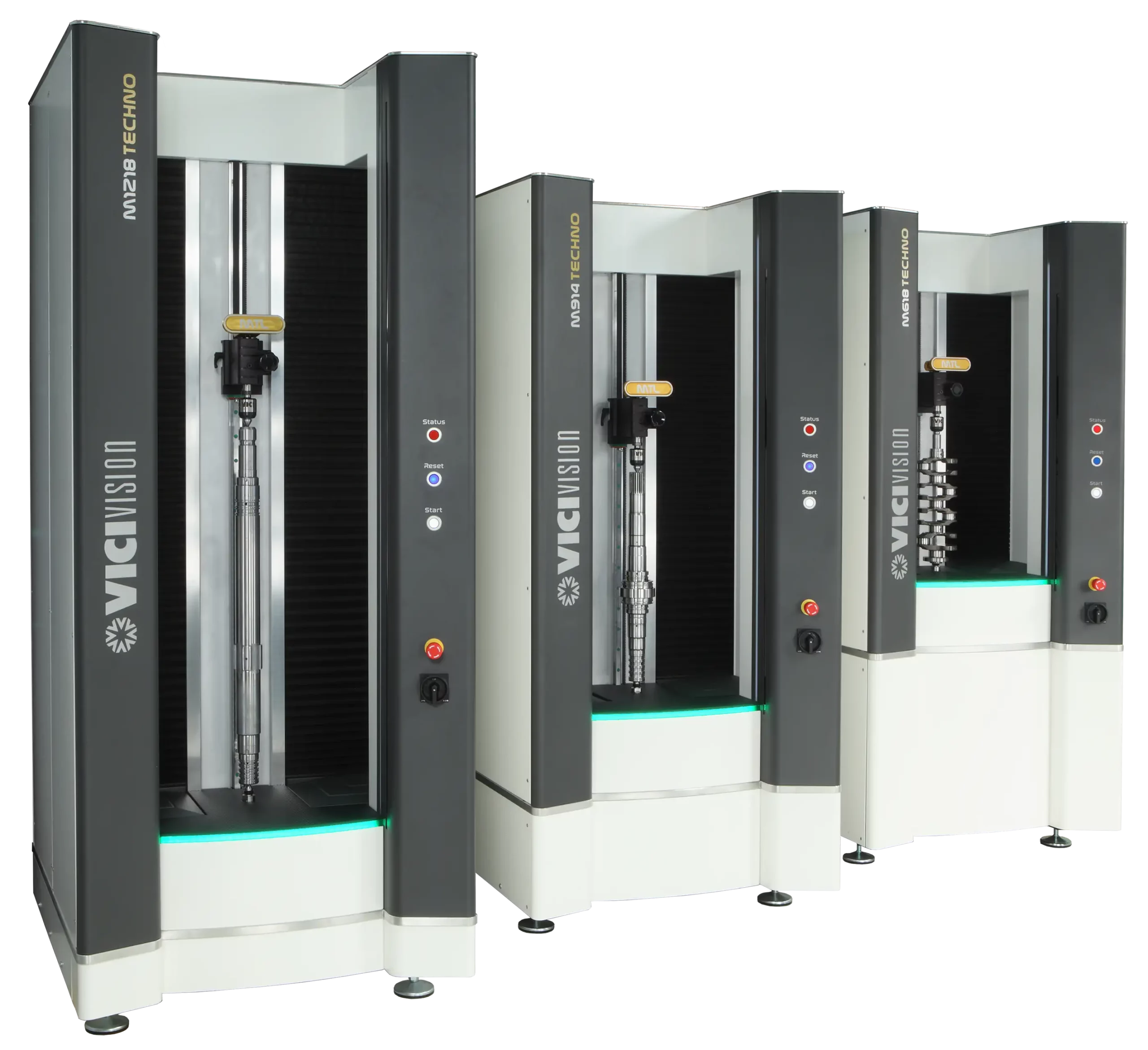

What machines are available in the TECHNO range?

The VICIVISION TECHNO Series comes in four applicable ranges, the M300, M600, M900 and M1200 enabling manufacturing facilities to find the solution bespoke to the budget and brief. Each model offers different measuring fields, but all offer micron-precision for turned parts and cylindrical measurements. You can see the full list of models at the end of this page.

- Benchtop models

- Intricate inspection of critical components

- Speed and accuracy for full capacity metrology

- Smooth and seamless large part measurements

High performance optics

The inherent accuracy of our automated inspection process ensures each part meets your exacting requirements – from “A” to “Z.” Our state-of-the-art optical measurement technology uses four CCD cameras and robotic light guides to capture highly detailed images of the internal geometry of the part enabling detailed imaging of even the most complex and micro features. This analysis provides the data you need to ensure that your part is up to spec, right down to the last detail.

Absolute uniformity

We understand that our customers want their parts to have consistency from start to finish, and the TECHNO range applies superior technology to provide full dimensional control, reducing rejects and increasing productivity.

Large Payload

The maximum load capacity on the M1209 is 30kg, increasing to 60kg with the M1214 and M1218.

All provide micron-precision performance in terms of accuracy and repeatability.

The maximum load capacity on the M1209 is 30kg, increasing to 60kg with the M1214 and M1218.

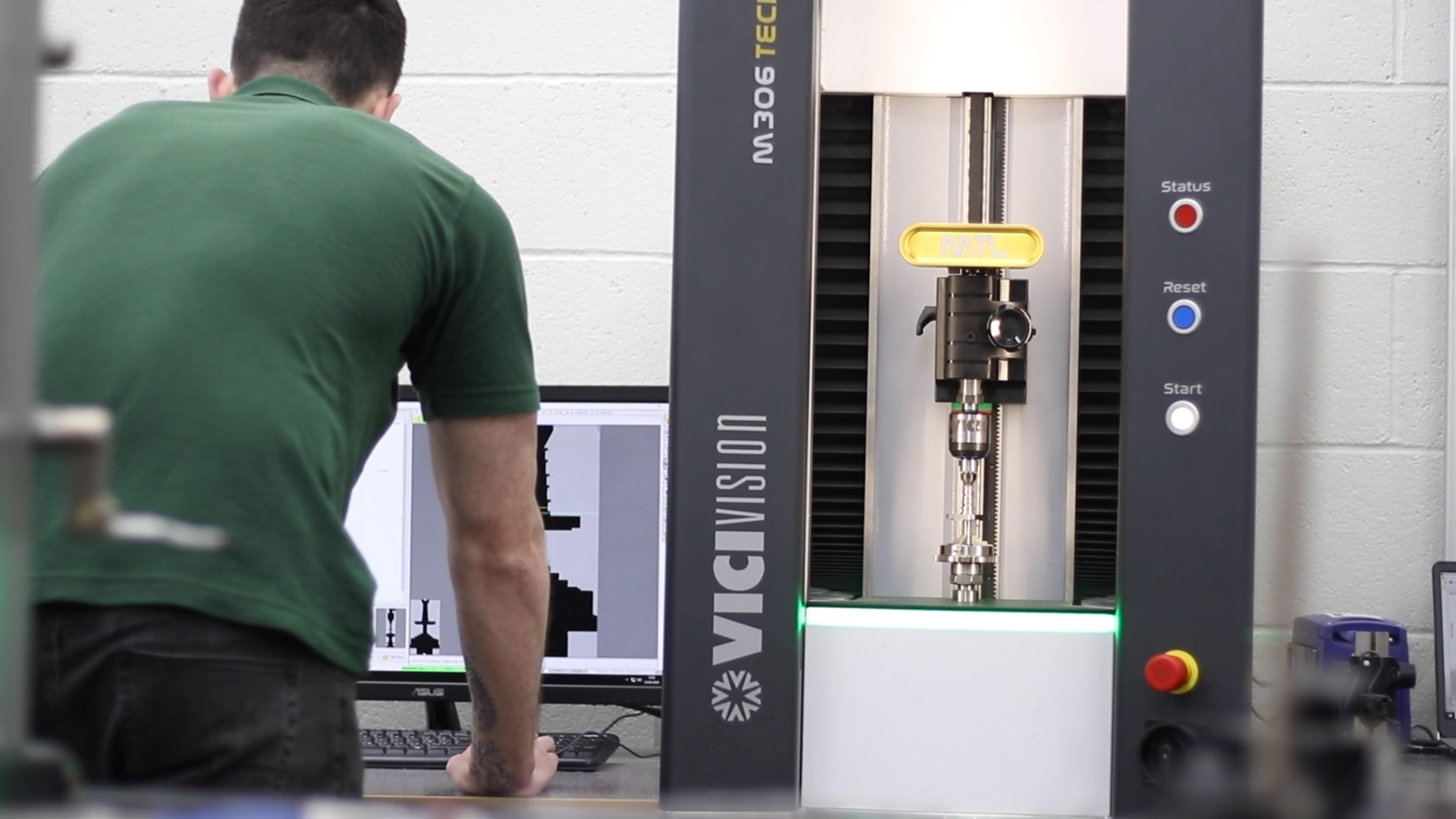

Inline Measuring

With a VICIVISION machine, measurement can take place directly next to your machine tools and even be embedded in the production process.

A turned part can be removed from the CNC lathe, placed into a VICIVISION machine stood directly beside it, and measured within seconds to assure compliance and quality.

By making the whole process faster and more efficient, time and money are both saved in exponential amounts. This not only represents a quick return on investment, but an overall boost to any manufacturing or engineering business as a whole.

1 top spec machine. 17 different measuring fields.

The Techno range is designed to provide a wealth of machine options in terms of measuring fields and maximum loads. This wide scope allows businesses to choose the specific machine for their unique demands.

With each machine from the smallest to largest having clear differences to each other, the VICIVISION Techno series of measurement machines offers a solution for any manufacturing or engineering environment.

The full range with VICIVISION UK is as follows:

- M304 – measuring field 300mm x 40mm, max loadable sizes 315mm x 120mm (10kg)

- M306 – measuring field 300mm x 60mm, max loadable sizes 315mm x 120mm (10kg)

- M309 – measuring field 300mm x 90mm, max loadable sizes 315mm x 120mm (30kg)

- M314 – measuring field 300mm x 140mm, max loadable sizes 315mm x 240mm (30kg)

- M318 – measuring field 300mm x 180mm, max loadable sizes 315mm x 240mm (30kg)

- M604 – measuring field 600mm x 40mm, max loadable sizes 625mm x 120mm (30kg)

- M606 – measuring field 600mm x 60mm, max loadable sizes 625mm x 120mm (30kg)

- M609 – measuring field 600mm x 90mm, max loadable sizes 625mm x 120mm (30kg)

- M614 – measuring field 600mm x 140mm, max loadable sizes 625mm x 240mm (30kg)

- M618 – measuring field 600mm x 180mm, max loadable sizes 625mm x 240mm (30kg)

- M906 – measuring field 900mm x 60mm, max loadable sizes 925mm x 120mm (30kg)

- M909 – measuring field 900mm x 90mm, max loadable sizes 925mm x 120mm (30kg)

- M914 – measuring field 900mm x 140mm, max loadable sizes 925mm x 240mm (60kg)

- M918 – measuring field 900mm x 180mm, max loadable sizes 925mm x 240mm (60kg)

- M1209 – measuring field 1250mm x 90mm, max loadable sizes 1300mm x 120mm (30kg)

- M1214 – measuring field 1250mm x 140mm, max loadable sizes 1300mm x 240mm (60kg)

- M1218 – measuring field 1250mm x 180mm, max loadable sizes 1300mm x 240mm (60kg)

No matter what model is employed, the Techno series captures high-resolution images that can detect the most minute of features. Accurate and repeatable to within mere microns, the machines allow for fast batch changes for rapid turned part measurement and increased efficiency.

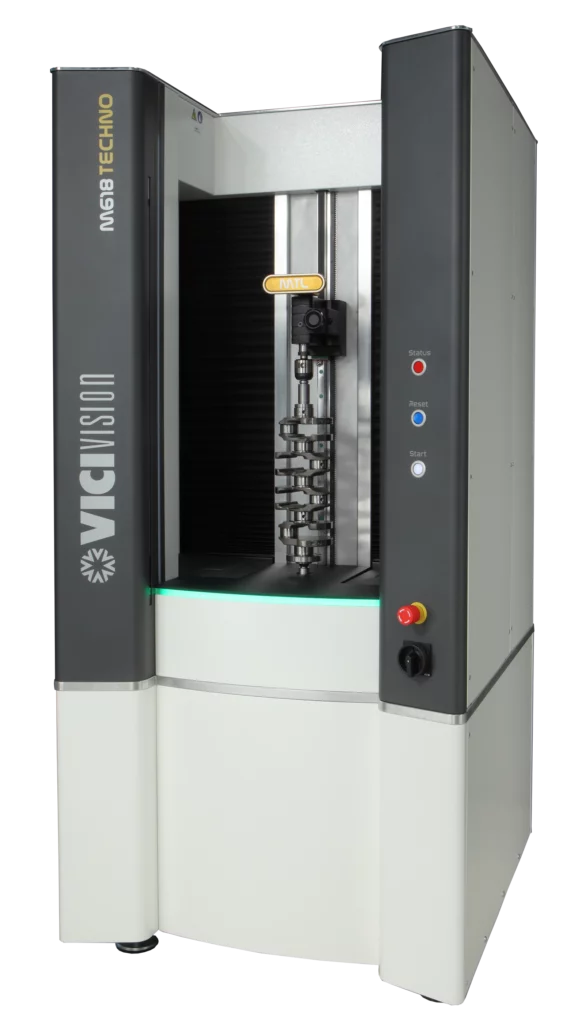

For extra accuracy and measurement data, a scanning probe can be used in conjunction with the optical sensors to gather part geometries and physical features. This also helps with pieces featuring greatly varied angles and sections such as crankshafts, allowing the most thorough readouts from your turned measuring solution.

The measuring area is LED illuminated and the measurement process is complemented by intuitive software. This makes any machine of the VICIVISION Techno range perfectly geared for independent operator usage with ease and speed.

Learn more about turned part measurement – speak to VICIVISION UK today.

Whether it’s a VICIVISION Techno or something else, our dedicated experts can help you with advice, guidance, and technical support. First-time purchase or help with a machine already in the workplace, we can see it through.