Versatility for large, complex workpieces

Best-in-class turned part measuring system for unparalleled accuracy, versatility, and speed, the Techno M1200 boosts productivity and quality control with cutting-edge optical technology. The expansive capacity of the M1200 Series caters to various needs, accommodating a length of 1250mm and diameters ranging from 90mm to 180mm. This versatile range ensures large capacity for batch measurements or large parts in a single, compact solution.

Flexibility to meet your needs

With multiple camera options, automated loading and unloading systems, and custom fixturing options, the Techno M1200 series can be configured to meet the specific needs of your application, whether it’s for small, simple components or large, complex parts.

High-precision motorised stages

The M1200 series features high-precision motorised stages that ensure precise measurements every time, even for components with tight tolerances. These stages can also be customised to meet the specific needs of your application, ensuring optimal performance and accuracy.

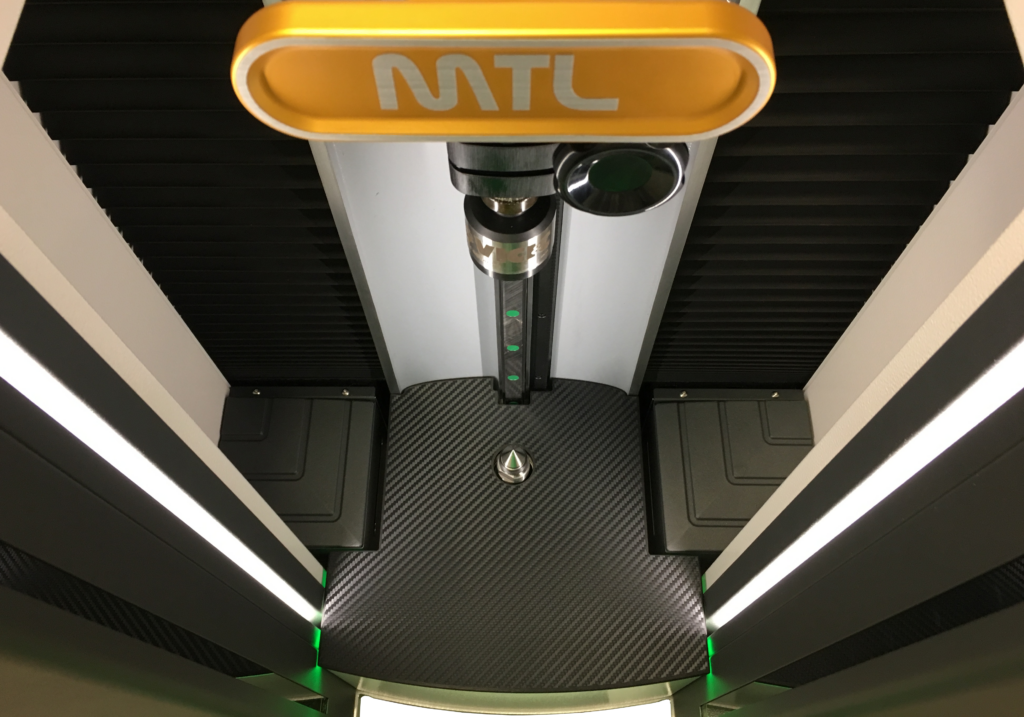

Advanced lighting systems

Advanced lighting systems provide optimal illumination, making it easy to capture accurate measurements and detailed analysis. With options for both coaxial and ring illumination, no detail goes unnoticed, even in the most challenging environments.

Unbeatable accuracy

The M1200 Series has an impressive measurement accuracy of up to 2 microns, and the flexibility to be configured with various options to meet specific measurement requirements.

Light up your inspection

The machines feature high-resolution cameras and an advanced LED lighting system, providing optimal illumination for accurate measurements with a range of up to 180mm in diameter and 1250mm in height.

Maximise your measurement

The dedicated measurement software includes a user-friendly interface and a range of tools for complex measurements and analyses, while training and support services are provided to help users maximise their investment.

Which M1200 machine is right for you?

M1206

| Length - 1250mm |

| Diameter - 60mm |

| Maximum component weight: 30 kg |

| Micron-precision performance |

| Optics: High-resolution telecentric lens |

| Illumination: Coaxial and 4-quadrant ring illumination |

| Ideal for: Small to medium-sized components including for aerospace and medical devices |

M1209

| Length - 1250mm |

| Diameter - 90mm |

| Maximum component weight: 60 kg |

| Micron-precision performance |

| Optics: Telecentric lens |

| Illumination: Coaxial and 4-quadrant ring illumination |

| Ideal for: Larger, complex components, including gears and transmission parts for automotive and aerospace applications |

M1214

| Length - 1250mm |

| Diameter - 140mm |

| Maximum component weight: 60 kg |

| Micron-precision performance |

| Optics: Telecentric lens with RGB LED lighting |

| Illumination: Coaxial and 4-quadrant ring illumination |

| Ideal for: Large and intricate components, such as engine blocks and other automotive parts |

M1218

| Length - 1250mm |

| Diameter - 180mm |

| Maximum component weight: 60/100 kg |

| Micron-precision performance |

| Optics: High resolution Telecentric lens |

| Illumination: Coaxial and 4-quadrant ring illumination |

| Ideal for: Large, intricate workpieces in high-production environments or requiring high precision measurement |

Book your

in-person demo

Book a free demo for the M1200 at our Advanced Innovation Centre where you can see the full scope of VICIVISION technology and how it can transform the way you work.

Download specification sheet

Get the full technical data on the M1200 today. Discover the key technical information including measuring fields, load sizes, accuracy and repeatability.